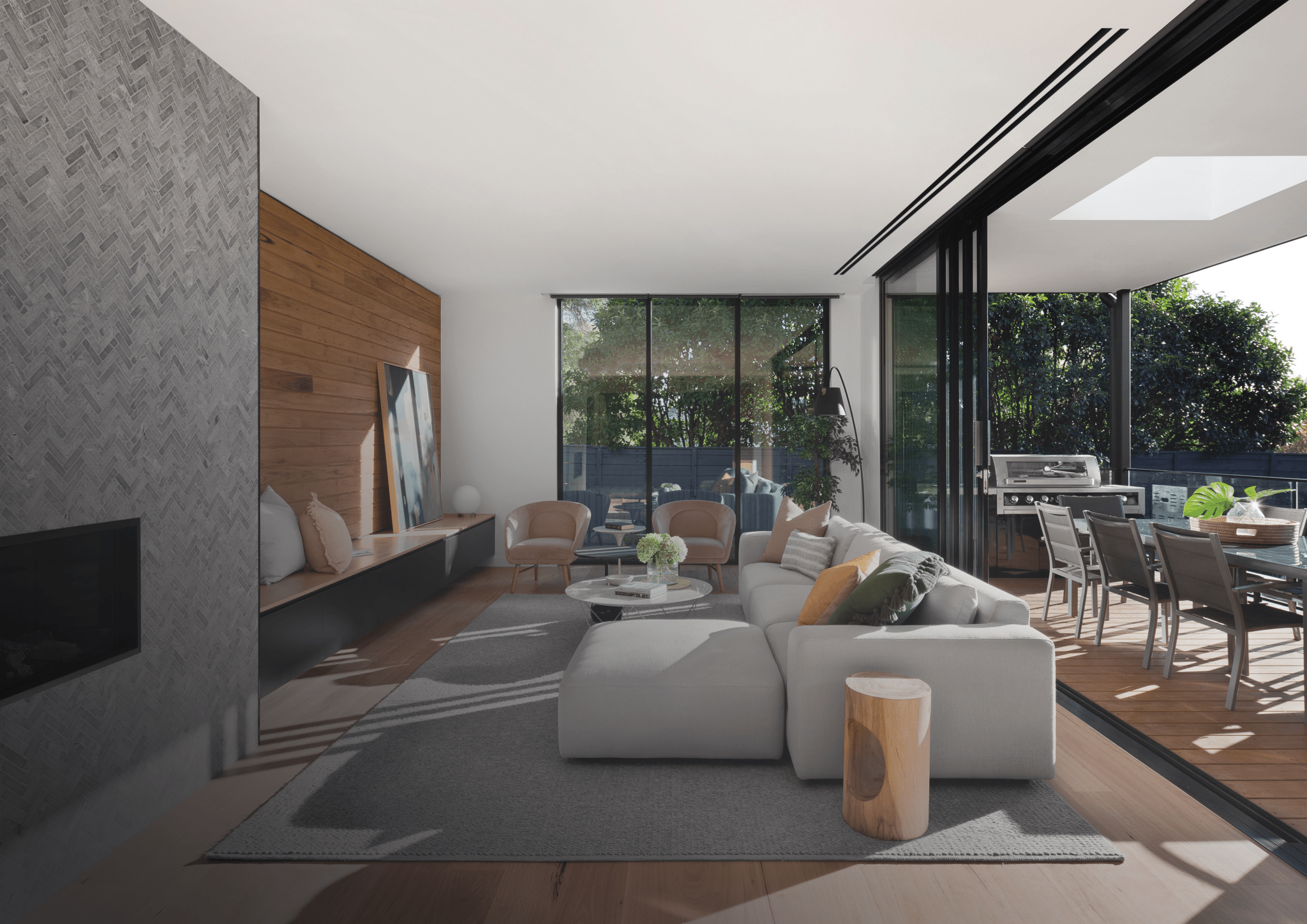

Discover how Ventmann solutions can be integrated into your design.

VENTMANN THERMO BOX - INVISIBLE HVAC INTEGRATION

INNOVATIVE DESIGN

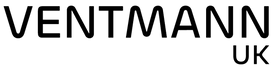

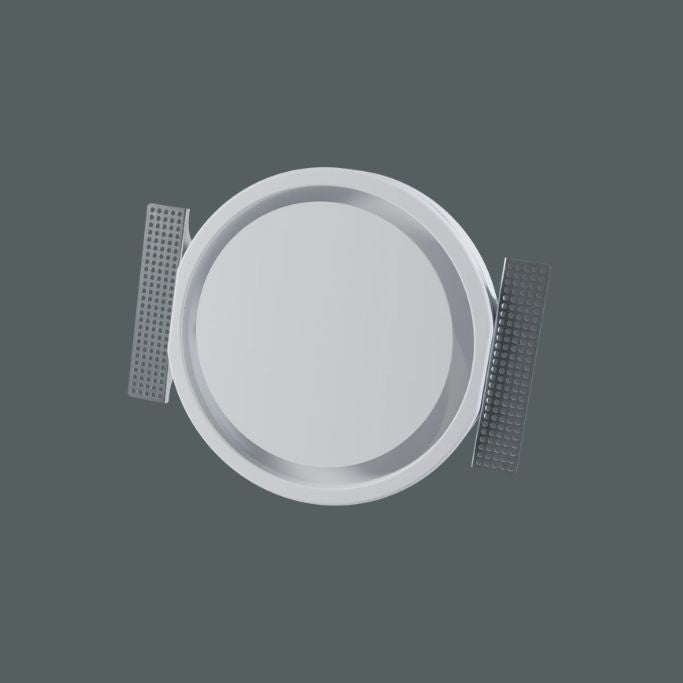

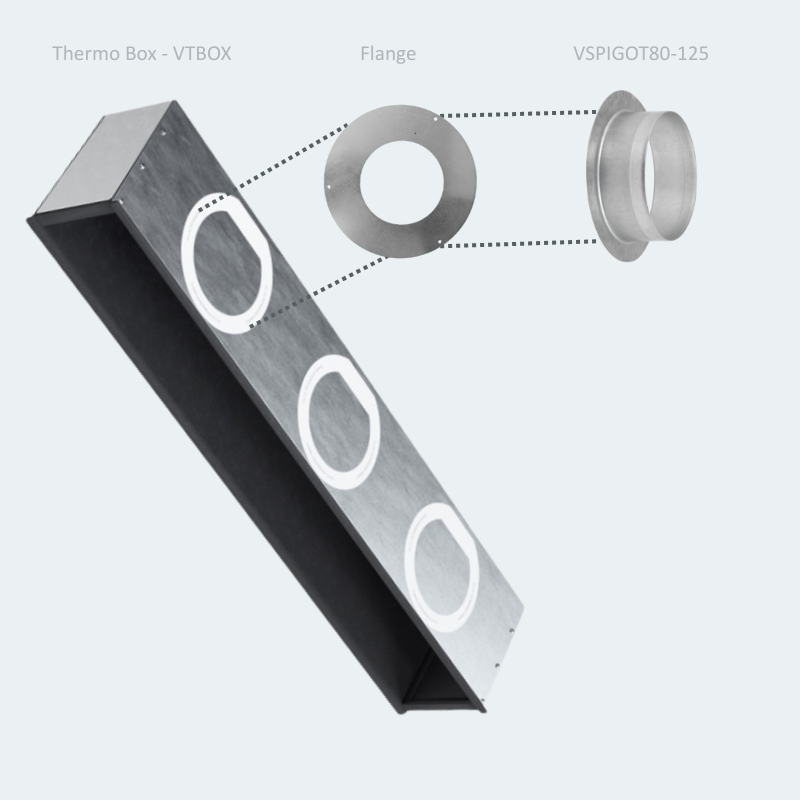

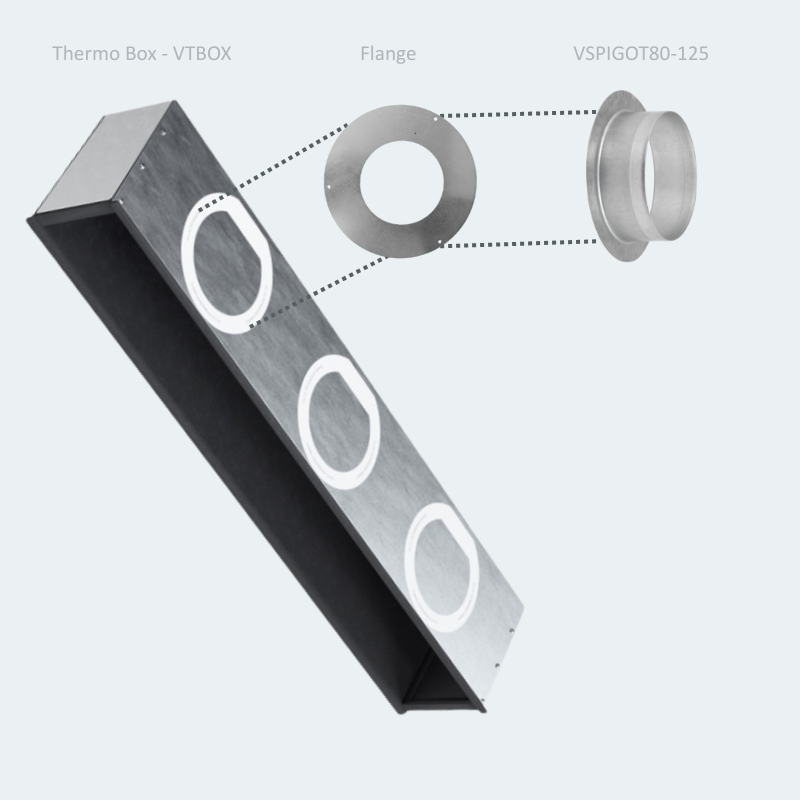

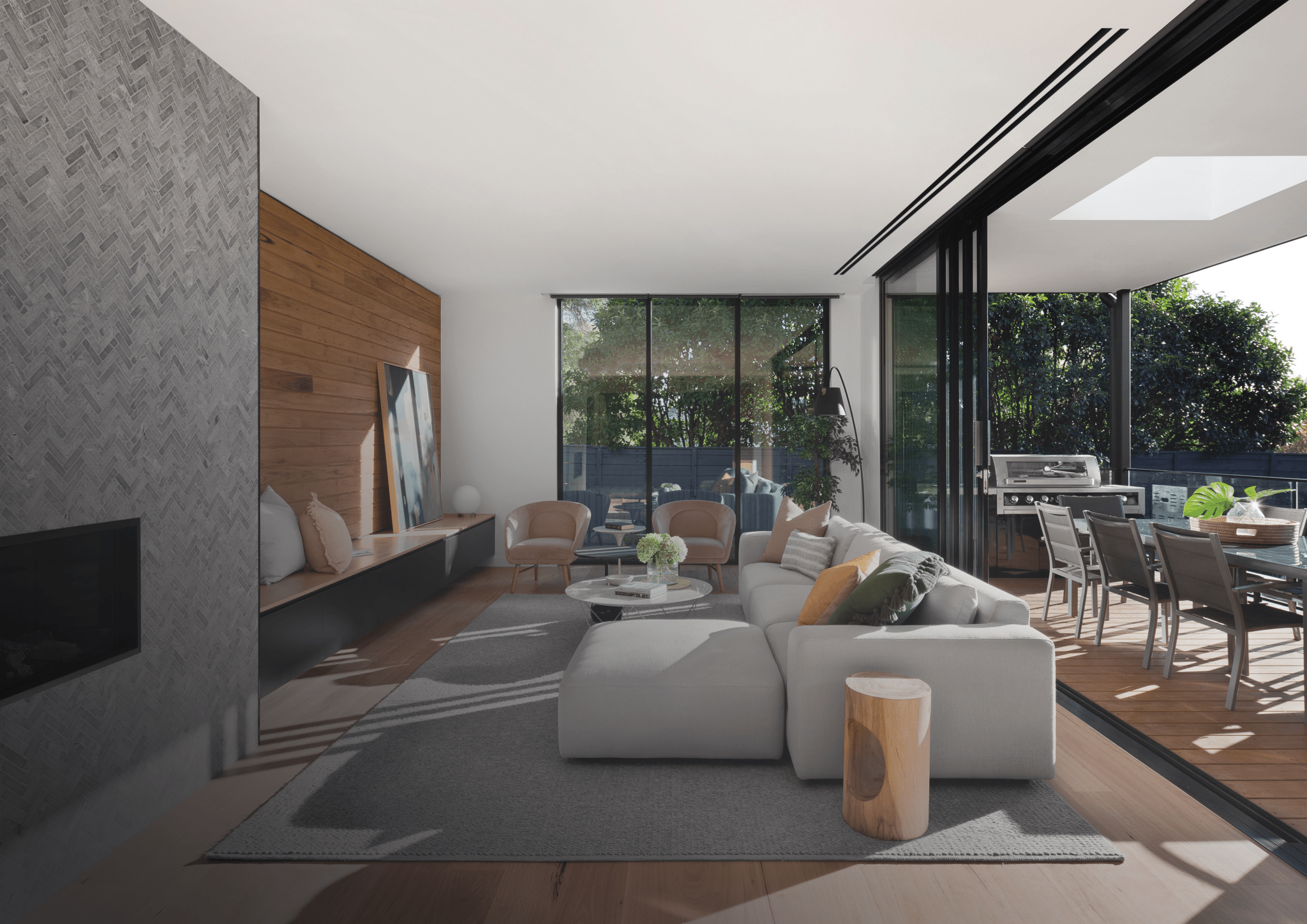

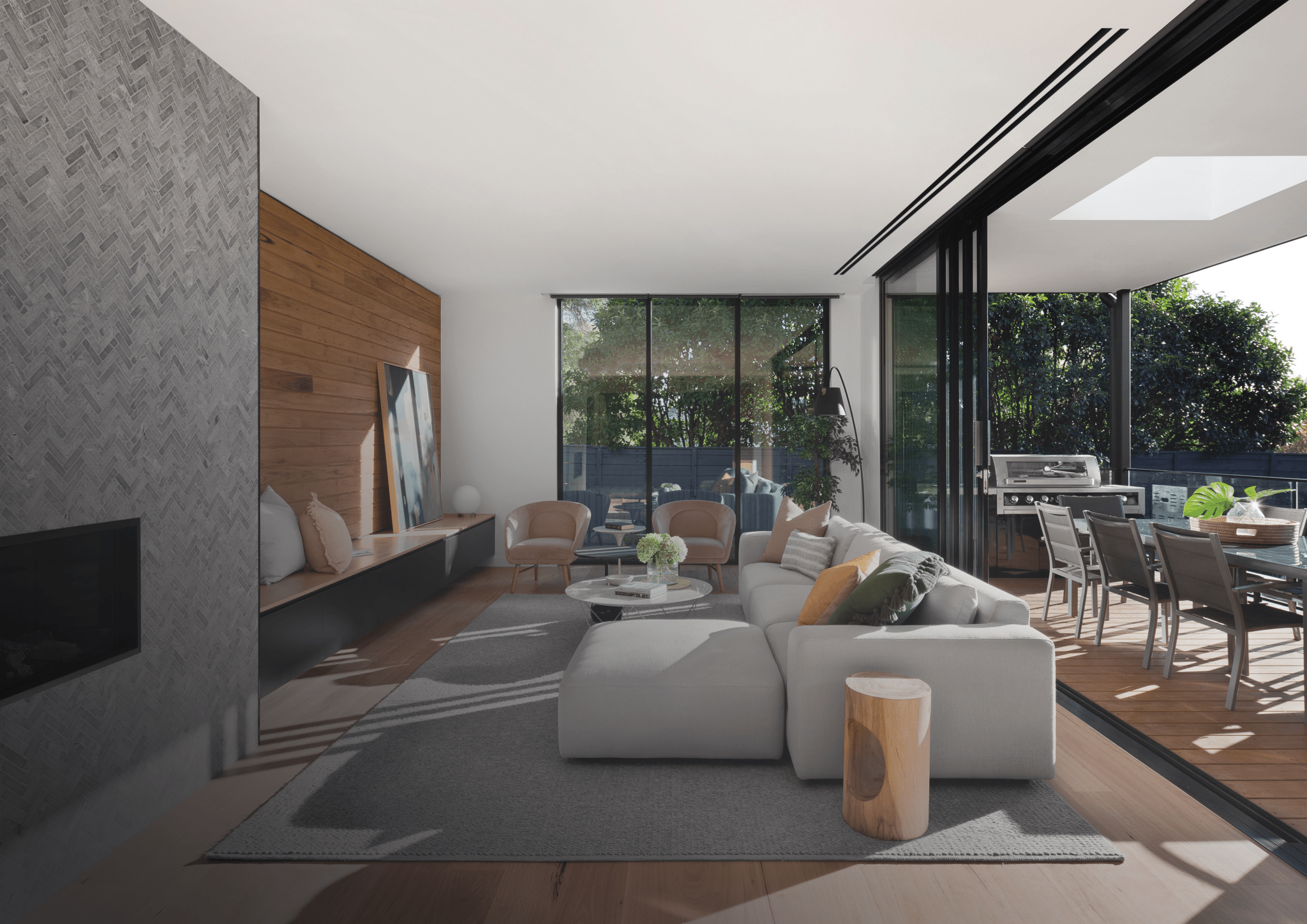

- Seamless Architectural Integration – The Ventmann Thermo Box is designed to work perfectly with our frameless gypsum diffusers, ensuring your HVAC system remains virtually invisible while maintaining a sleek, modern interior finish.

- Compatible with Minimalist Designs – Whether paired with linear, circular, or square diffusers, Thermo Boxes support near-invisible installations in plasterboard walls or ceilings, ideal for residential and commercial spaces requiring a refined architectural look.

- Enhanced Performance & Design – Built to complement Ventmann diffusers, Thermo Boxes ensure optimal airflow, noise reduction, and energy efficiency, all while preserving the aesthetic integrity of your space.

How to connect

ABOUT VENTMANN THERMO BOX

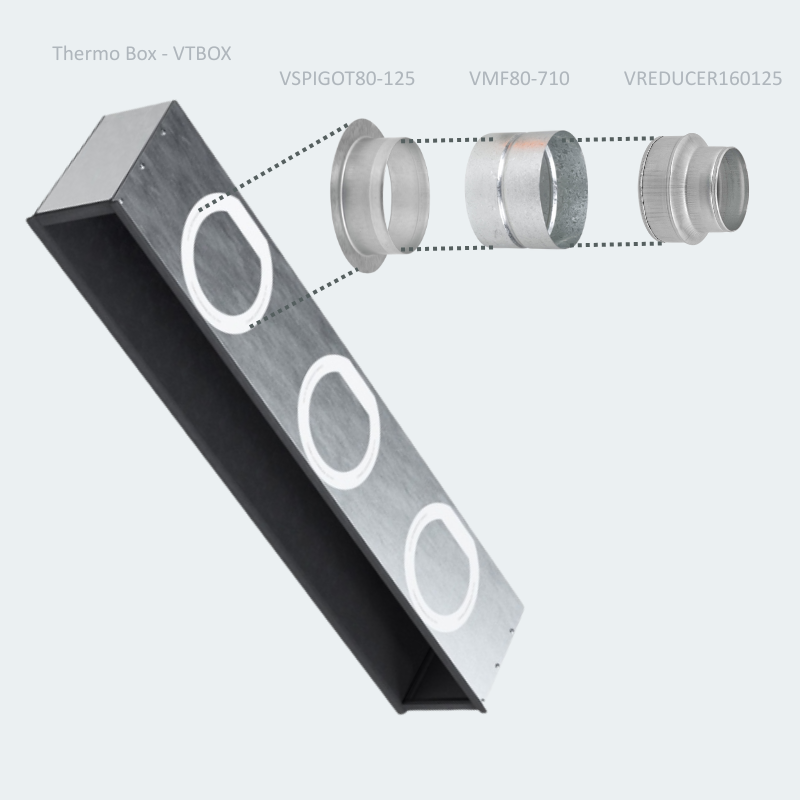

- Flat-Packed & Easy to Assemble – Ventmann Thermo Boxes arrive flat-packed for convenient transport and storage. Quick assembly on site with the included screws and SQ2 bit makes installation simple and efficient.

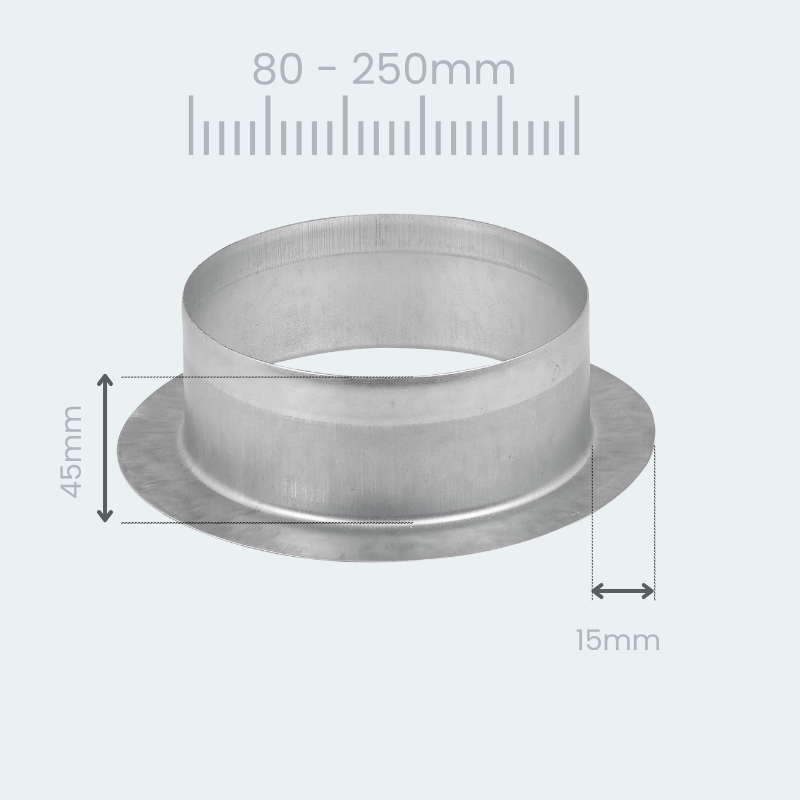

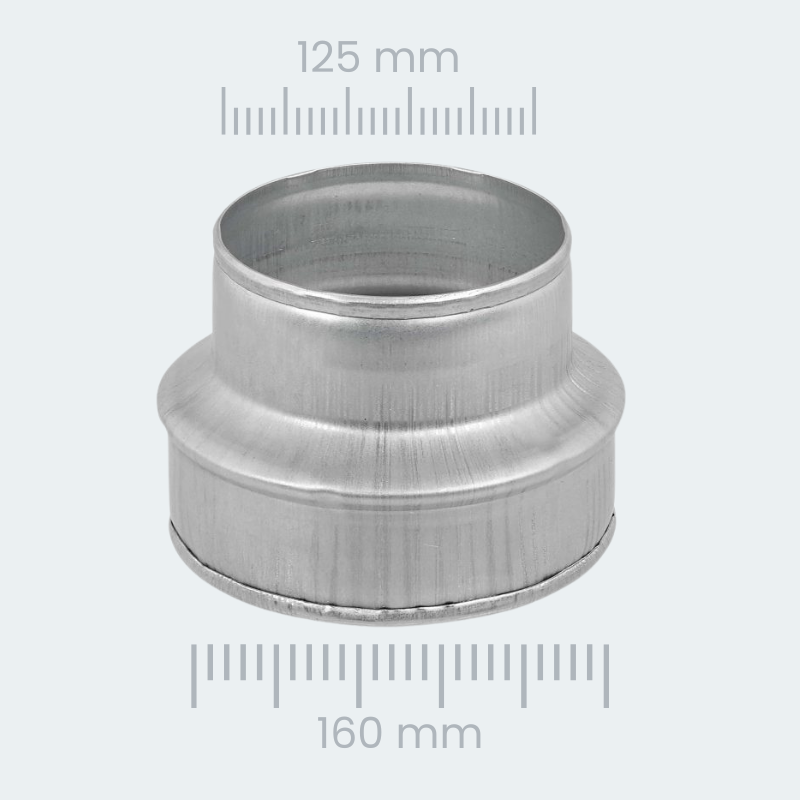

- Versatile & Customisable – Designed with pre-scored knock-outs (125mm, 160mm, 200mm) for easy adaptation to your ducting needs. Compatible with standard ducting spigots for a secure, sealed connection.

- Perfect Fit for Linear Diffusers – Available in three lengths (625mm, 1000mm, 1250mm) and width codes A, B, C to match Ventmann slot diffusers, ensuring optimal airflow and performance.

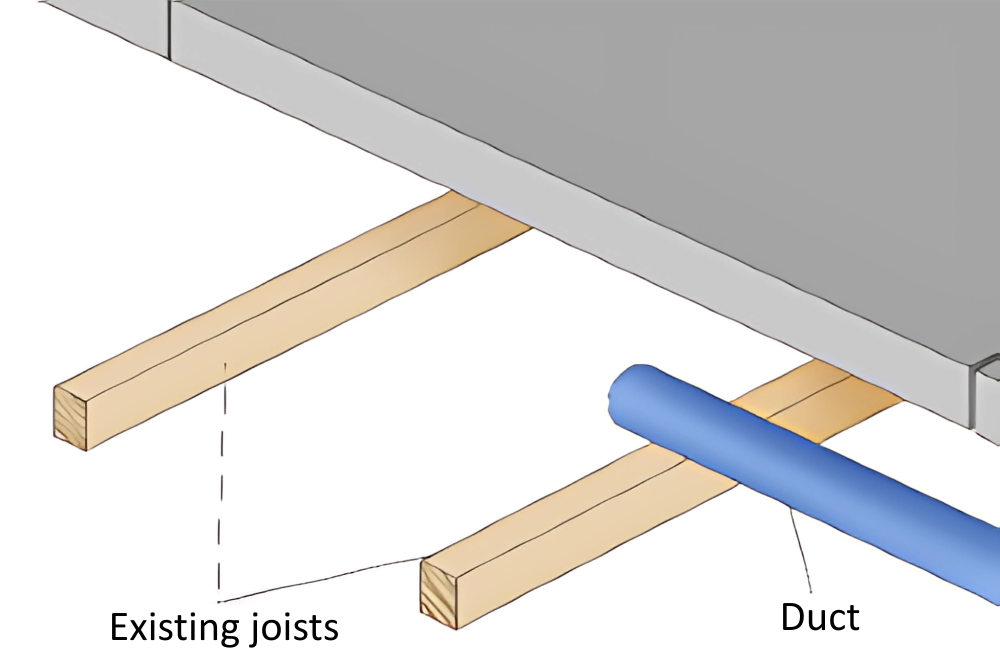

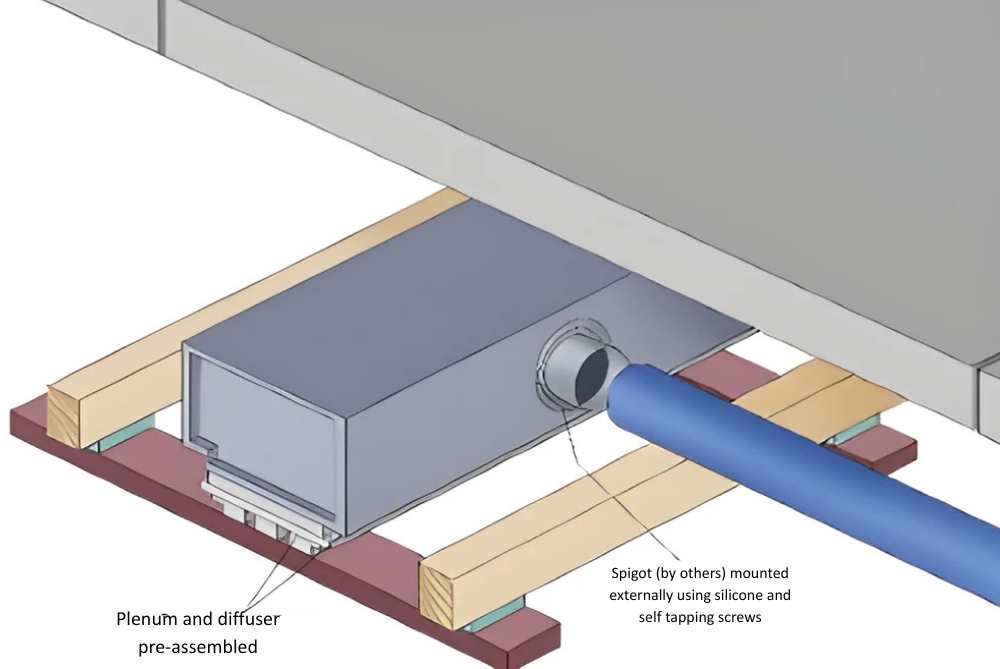

Step 1

Line Diffuser Installation Instructions

Pre-position the ventilation duct in the ceiling

void, above, through, or alongside the ceiling

joists. If required, purchase reducer(s) to suit

the size of duct and spigots (by others).

Step 2

Fit temporary batons with plasterboard

spacers that are the same thickness as the

final ceiling plasterboard sheet. Where metal

plasterboard rails are employed, suitable self

tapping screws will be required.

Step 3

Fit pre-assembled* diffuser, plenum box and

spigot(s) on top of temporary batons. Note

that spigot (by others) is surface mounted on

plenum using self-tapping screws and

silicone.

*Using screws provided

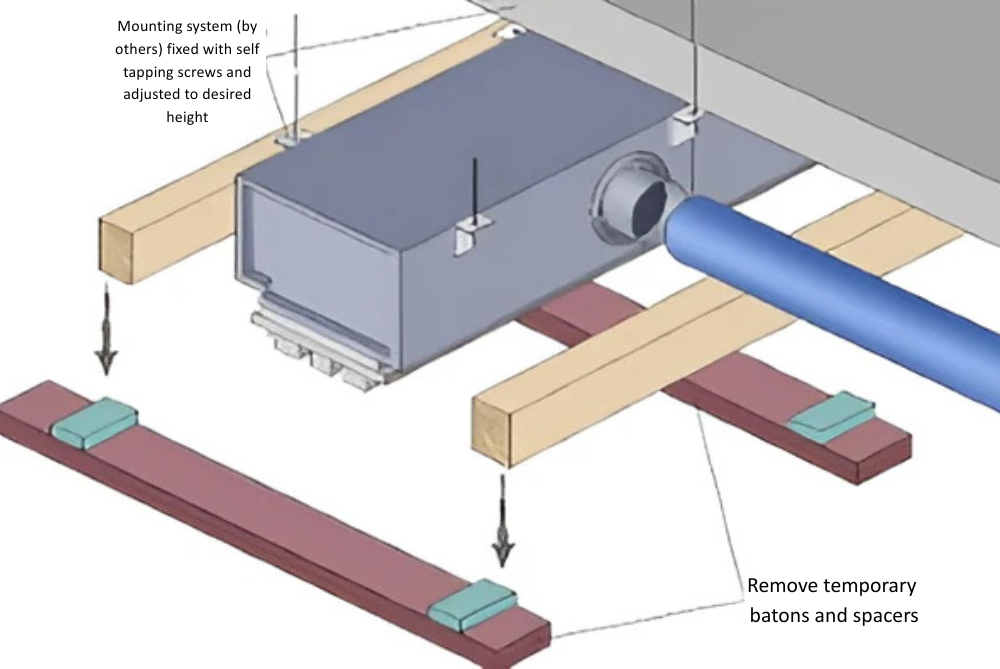

Step 4

Fix plenum to upper surface using proprietary

fixings (Unistrut etc) (by others). Fix to

plenum with self-tapping screws. Adjust

height of the plenum so that the face of the

diffuser just touches the top of the batons.

Step 5

Remove temporary batons and plasterboard

spacers. Measure and cut the hole in the

main plasterboard sheet. Lift the

plasterboard sheet to meet the diffuser and

fix in place as normal using plasterboard

screws.

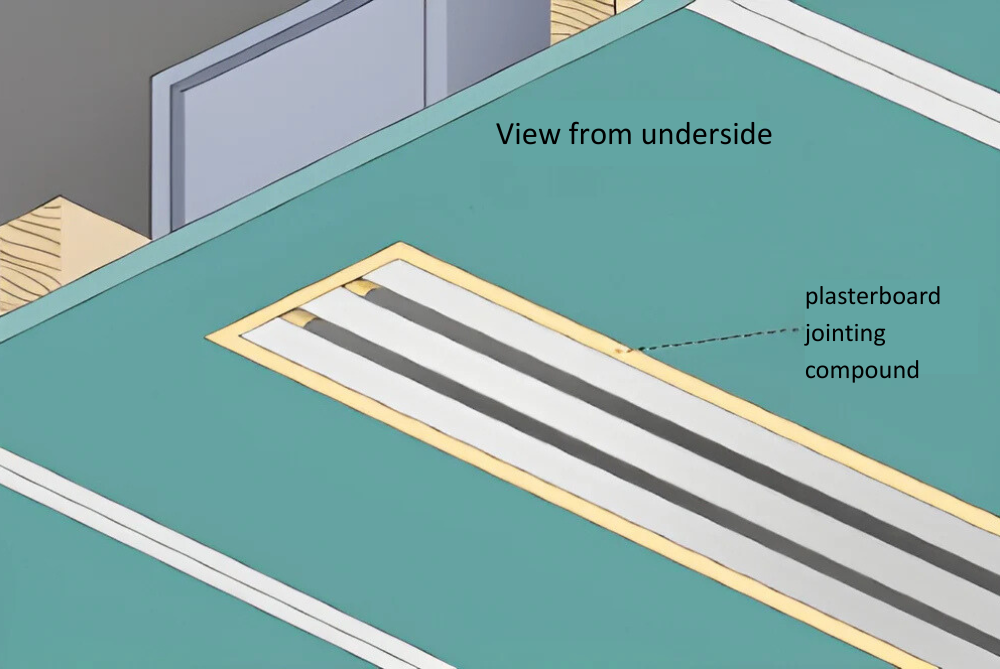

Step 6

From the underside, use a jointing compound

to fill the gap between diffuser and

plasterboard. If required, move magnetic

blocks to desired length and fix in place using

jointing compound. Sand and paint.

Related Blog Posts

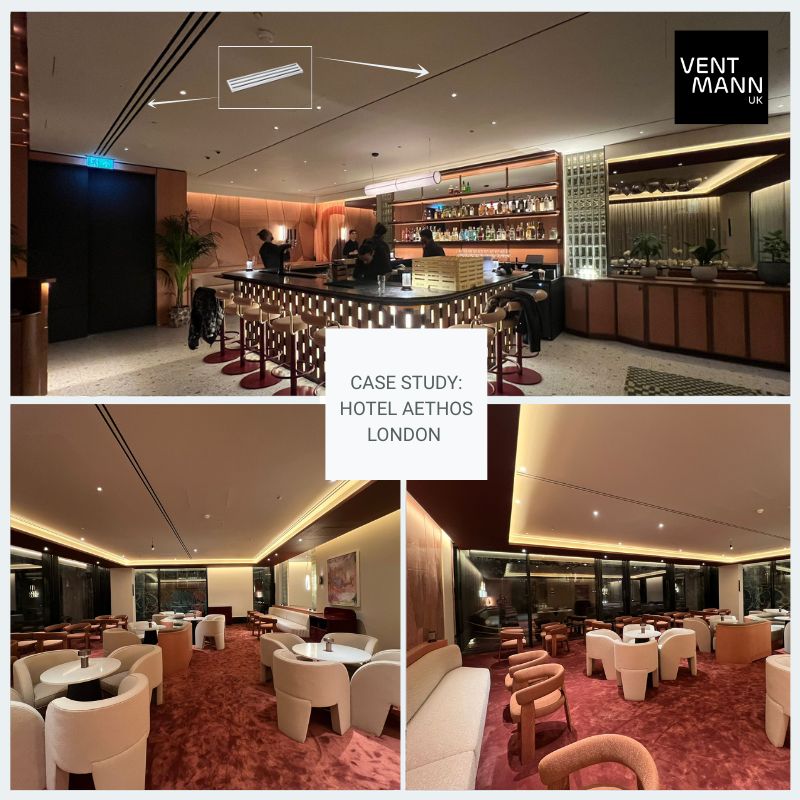

Architectural Air Diffusers at Aethos London: A Seamless Integration of Design and Performance

In high-end hospitality design, ventilation is no longer a purely technical consideration—it is an integral part of the architectural language.

Ventmann UK to Exhibit at London Build Expo 2025 – The UK’s Largest Construction Show

What Is a Linear Diffuser? Everything You Need to Know

In modern interior design and HVAC (Heating, Ventilation, and Air Conditioning) systems, linear diffusers have emerged as a go-to solution for spaces that demand both style and functionality.